Yorkshire Water Trials With ‘Nu Drain’ Prove Successful

Site: The trials were carried out on multiple sewer systems serving domestic properties throughout Leeds, Hull and Barnsley.

System: Clay and pitch-fibre sewer drainage pipes ranging from 100mm (4”) to 150mm (6”). These pipes were all located in tight, difficult to access spaces extending from homeowners’ landscaped gardens to busy main street roads.

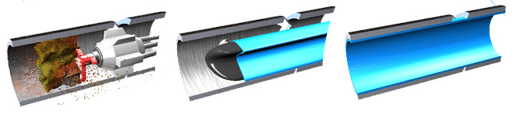

Problem: The sewer drainage systems serving the residential trial areas were not performing to an acceptable standard due to problems such as blockages, damaged pipes and cracked joints. One pipe in particular had a displaced joint which had caused a 1m section of the pipe to drop down 50mm. This caused blockages, poor flow, and leaks in times of heavy use. Borescope pictures also revealed another trial pipe had significantly reduced diameter (from 100mm to 50mm in places) due to severe internal damage and corrosion. This required regular maintenance visits from Yorkshire Water’s sewerage crew in order to keep the line clear and functioning.

Circumvention: Traditional pipe replacements would have cost the customer significantly more time, effort, disruption and money to complete. Yorkshire Water’s community strategy aims to minimise disruption to the customer and a repipe project on the various sites would not have conformed to this strategy. Similarly, the company have a ‘green initiative’ in place which aims to reduce their carbon footprint. Fuelling excavations, busying up roads, and sending dug-up pipes and road to landfill would also not have conformed to this strategy.

Solution: Yorkshire Water were attracted to CapCon for their ‘no-dig’ technology. CapCon technicians were able to successfully rehabilitate all trial areas without causing any disruption to homeowners and road users alike. First, pneumatic pipe cleaning tools were used to restore all pipes back to their original diameters. Thorough inspections were carried out to ensure all pipes were clean and clear before the Nu Drain liner was installed. This liner was pulled into place, inflated, and cured to the existing pipe to create a new, smooth surface. This offered a cost effective, permanent solution to the customers recurring problems which they were extremely satisfied with. The CapCon technique saved one customer in particular over £14,500 compared to a conventional pipe replacement solution.

“This is particularly innovative and we’ve been looking for a technology that can do this. As a forward-thinking company, we really don’t want to have to excavate”

Bob Watterson, Technical Support Engineer at Yorkshire Water